Pouch Packaging MachineryOur company offers highly-productive range of Packaging Machinery such as Automatic Salt Pouch Packing Machine, Automatic Snacks Hi-Speed Collar Type Packing Machine, Spices Powder Packaging Machine, etc. They are efficient machines designed using food-grade stainless steel to ensure no abrasion and rusting for years to come. This array of Packaging Machinery is used for packaging liquids, powdered and other products owing to rapid sealing and excellent packaging functions. They are designed to fill bottles, bags and packets of different sizes and dimensions.

|

Water Packing Machine

Price: 1650000 INR /Liter

- Minimum Order Quantity 1-2

- Price 1650000 INR

- Unit of Measure Liter/Liters

- Unit of Price Liter/Liters

A Water Packing Machine efficiently packages water into pouches at a speed of 35 pouches per hour. This machine features key components such as a filling nozzle, sealing system, and pouch forming unit, each ensuring precise filling, secure sealing, and accurate pouch creation. Powered by a PLC-based operating system, it offers user-friendly controls. Manufactured using advanced design and engineering technologies, it guarantees durability and high efficiency. Available in various sizes, it is ideal for industries like food & beverage, pharmaceuticals, and personal care. The machine benefits businesses by enhancing productivity, reducing labor costs, and ensuring consistent packaging quality.

- Feeling Range : 200 ML

- Packing Speed: 35 pouches per hour

- Accuracy: +/- 1%

- Model : HP-104

- Dimensions : H-2.35 x W-0.91xD.-0.80 Mtrs.

- Weight : 450 Kgs.

- Electricity :230v. 10,50c/s

- Peak Power : 4 Kw

- Power Consumption : 1Kw/Hr.

- Accuracy : +/- 5ml

Soap Packing Machine

Price: 450000 INR /Gram

- Minimum Order Quantity 1-2

- Price 450000 INR

- Unit of Measure Gram/Grams

- Unit of Price Gram/Grams

The Soap Packing Machine efficiently packs soaps into pouches at a speed of 45-50 pouches per minute. Key components include a filling system for precise soap placement, a sealing mechanism for secure packaging, and a labeling unit for clear product information. The machine operates on a PLC-based system, ensuring high accuracy and ease of use. Built with advanced engineering technologies, it guarantees reliability and long-lasting performance. Used widely in the personal care, cosmetics, and FMCG industries, it helps streamline production, reduce labor costs, and maintain packaging consistency, improving overall operational efficiency and product quality.

- Model : HP-098

- Speed : 45-50 pouches per min

- Sealing : Centre Seal

- Power Required : Motor : 1.5 HP AC with AC Drive

- Voltage : 220 Volts

- Phase : Single/Three

- Load : 3KW

- Weight : 480 Kg. (Approx.)

Noodles Packing Machine

Price: 450000 INR /Gram

- Minimum Order Quantity 1-2

- Price 450000 INR

- Unit of Measure Gram/Grams

- Unit of Price Gram/Grams

The Noodles Packing Machine efficiently packs noodles into pouches at a speed of 55-60 pouches per minute. Key components include a volumetric filler for precise portions, a sealing system for airtight packaging, and a pouch forming unit for consistent shapes. Driven by an advanced PLC-based operating system, it ensures smooth operations. Manufactured using cutting-edge engineering technologies, the machine offers durability and high performance. Available in various sizes, its widely used in the food processing, FMCG, and snack industries. This machine boosts production efficiency, reduces labor costs, and guarantees uniform packaging, ensuring quality and freshness in every pouch.

- Sealing Type : Center Sealing

- Feeding Type : Conveyor Feeding

- Speed : 55 60 Pouches per Minute

- Packing Material : Laminated Film(Heat Sealable)

- Power Required : Motor : 1.5hp Ac with Ac Drive

- Voltage : 220 Volts

- Phase : Single Phase/Three Phase

- Load : 3kw

- Machine Dimensions(mm) : 3000x1700x1800

- Machine Weight : 580kg(Approx.)

- Model No. : HP098

Chips Packing Machine

Price: 750000 INR /Kilograms

- Minimum Order Quantity 1-2

- Price 750000 INR

- Unit of Measure Kilograms/Kilograms

- Unit of Price Kilograms/Kilograms

A Chips Packing Machine is a specialized automated system designed to efficiently pack chips and snacks into bags or pouches. Key components include a feeder for chips, a conveyor belt for transport, a weigh hopper for accurate filling, and a sealing system for bag closure. It uses an electronic control system for precision and efficiency. Engineered with robust materials, the machine ensures durability and high performance. Commonly used in the food processing, packaging, and snack industries, it increases production speed, reduces labor, and ensures consistent packaging. Available in various sizes, it offers flexibility to meet diverse packaging needs.

- Pack Size : 50gm1kg

- Filling Style : Linear Weigh Filler

- Packing Speed : 10 35 Pouches per Minute(Depending on the filling volume)

- Packing Material : Laminated Film(Heat Sealable)

- Packing Style : Center Sealing

- Weight Accuracy : +/1.5%

- Display PLC Type : Colored Touch Screen

- Model No. : HP101(4 Head)

Dip Tea Packing Machine

Price: 1250000 INR /Milligram

- Minimum Order Quantity 1-2

- Price 1250000 INR

- Unit of Measure Milligram/Milligrams

- Unit of Price Milligram/Milligrams

A Dip Tea Packing Machine is designed to efficiently pack tea bags or pouches for dip tea products. Key components include a hopper for tea leaves, a filling system for accurate dosing, a sealing unit for pouch closure, and a labeling system for branding. The machine uses an advanced PLC control system for smooth operation and precise packing. Made with high-quality materials, it offers durability and high performance. Commonly used in the tea industry, it enhances productivity, reduces waste, and ensures consistency. Available in various sizes, it caters to different production volumes and packaging preferences, improving overall efficiency.

- Product : Tea

- Packaging Range : 2gm3gm

- Measuring : Volumetric Cup Filler

- Packaging Speed : 60 70 bags per minute

- Bag Size (L x W)mm : 2024x4055

- Thread Length : 155mm

- Inner Bag Size(L x W)mm : 5075 x 5075

- Outer Bag Size (L x W)mm : 70120 x 6090

- Power : 220v/50Hz/3.7kw

- Machine Dimension(L x W x H)mm : 1200x700x1800

- Machine Weight : 500kg

- Model No. : HPDB04

Continuous Band Sealer

Price: 115000 INR /Piece

- Minimum Order Quantity 1

- Price 115000 INR

- Unit of Measure Kilograms/Kilograms

- Unit of Price Piece/Pieces

A packaging device known as a Continuous Band Sealer constantly closes bags or pouches while they are being made. The sealing band, which forms the seal, the heating element, which supplies heat for sealing, the conveyor belt, which moves things for smooth operation, and the control panel, which controls temperature and speed, are essential parts. Because of its automated method, it can seal quickly and effectively. The equipment guarantees accuracy and longevity by utilising cutting-edge engineering and manufacturing technology. It is utilised in the culinary, pharmaceutical, and chemical industries and comes in a variety of sizes. The Continuous Band Sealer increases product shelf life, lowers labour costs, guarantees airtight sealing, and improves packaging efficiency.

- To Pack : Atta

- Power Supply : 220240v/5060hz 1 Phase

- Power Consumption : 2kw

- Sealing Speed : 012m/Min

- Sealing Width : 615mm

- Sealing Film Thickness : 0.020.08mm

- Machine Contact Part; MS powder coated

- Machine Dimensions(mm): (L)1075mm X (W)480mm X (H)650mm

- Sealing Strength : Up to 10kg

- Model No .: HP105A

Oil Packing Machine

Price: 450000 INR /Liter

- Minimum Order Quantity 1-2

- Price 450000 INR

- Unit of Measure Liter/Liters

- Unit of Price Liter/Liters

Oils in the 500-1000 ml range are efficiently packaged using the Oil Packing Machine. A capping system for safe closure, a sealing device for airtight packaging, and a volumetric filler for accurate measures are essential parts. It has an easy-to-use PLC technology that guarantees excellent precision and seamless operation. The machine is made with cutting-edge engineering technology to ensure longevity and peak performance. It is frequently used in the chemical, food, and cosmetics sectors to increase production speed, decrease manual labour, and preserve packaging consistency. Businesses gain from this machine's increased productivity, decreased waste, and guaranteed product quality.

- Packaging range : 500-1000ml.

- Speed : 15-18 pouches per minute

- Sealing : Centre Side

- Power Required : Voltage : 220 Volts

- Phase : 1 phase

- Load : 1 KW/Hr.

- Weight : 450 Kg. (Approx.)

- Model : HP-104

Maida Packing Machine

Price: 650000 INR /Kilograms

- Minimum Order Quantity 1-2

- Price 650000 INR

- Unit of Measure Kilograms/Kilograms

- Unit of Price Kilograms/Kilograms

A Maida Packing Machine is a specialized equipment used for packing Maida (refined wheat flour) into bags for commercial distribution. Key components include a hopper for flour input, a weighing scale for accuracy, a pouch forming system, and a sealing mechanism for secure packing. It operates through automated systems that control speed, weight, and sealing quality. Manufactured with advanced engineering technologies, the machine ensures precision, durability, and high efficiency. Its compact design suits varying production scales. Common in food processing industries, it improves productivity, reduces labor costs, and ensures consistent product packaging for retail or wholesale use.

- Pack Size : 10gm 1kg

- Packing Speed : 15 60 Pouches per Minute(Depending on the filling volume)

- Filling Type : Volumetric Servo Auger Filler

- Packing Material : Laminated Film(Heat Sealable)

- Packing Style : Center Sealing

- Accuracy : +/1%

- Machine Dimensions(mm) : 1500x1200x3000

- Machine Weight : 1050kg(Approx.)

- Material Contact Parts : SS:304

- Model No. : HP102

Khaini Packing Machine

Price: 1500000 INR /Piece

- Minimum Order Quantity 1-2

- Price 1500000 INR

- Unit of Measure Gram/Grams

- Unit of Price Piece/Pieces

An automated machine called a Khaini Packing Machine is used to package Khaini, a type of chewing tobacco, into sachets or pouches. A dosing system for accurate filling, a sealing mechanism, a packaging device, and a hopper for storing Khaini are essential parts. Accuracy and fast performance are guaranteed by the machine's sophisticated control system. Constructed from sturdy, high-quality materials, it is effective and requires little upkeep. It is mostly utilised in the packaging and tobacco industries, where it lowers manual labour, guarantees consistent packing, and increases efficiency. It provides versatility to accommodate varying packaging capacities and requirements because it comes in a variety of sizes.

- Fully Automatic Filter Khaini Packing Machine (High Speed Intermitted Type)

- To Pack : Filter Khaini

- Filling Type : Volumetric air filling system

- Sealing Type : Center Seal Pillow Type

- Packaging Range : 3 4mg

- Packing Speed : 200-250 Pouches per Minute(Depend on weight & size)

- Accuracy : +/-1%

- Packing Material : Non-woven filter paper

- Power : 3kw,440v AC, 50hz, 3 phase

- Compressor : 3cu mtrs/hr. @ 8bar

- Dimensions(mm) : 1900x900x1250

- Weight : 1000kg(Approx.)

- Model No. : HP-111

Rusk Packing Machine

Price: 450000 INR /Piece

- Minimum Order Quantity 1

- Price 450000 INR

- Unit of Measure Kilograms/Kilograms

- Unit of Price Piece/Pieces

A Rusk Packing Machine is designed to automate the packaging of rusks into pouches or boxes. Key components include a hopper (holds rusks), filling mechanism (dispenses the correct amount), sealing system (seals packages tightly), and a control panel (monitors and manages the process). It operates using advanced PLC systems for precise control. Manufactured with stainless steel for hygiene and durability, it is suitable for high-speed production. Used in the bakery and food processing industries, this machine boosts efficiency, reduces labor, ensures packaging consistency, and improves overall productivity. It comes in various sizes and automatic or semi-automatic types.

- Sealing Type : Center Sealing

- Feeding Type : Conveyor Feeding

- Speed : 55 60 Pouches per Minute

- Packing Material : Laminated Film(Heat Sealable)

- Power Required : Motor : 1.5hp Ac with Ac Drive

- Voltage : 220 Volts

- Phase : Single Phase/Three Phase

- Load : 3kw

- Machine Dimensions(mm) : 3000x1700x1800

- Machine Weight : 580kg(Approx.)

- Model No. : HP098

Sugar Packing Machine

Price: 425000 INR /Kilograms

- Minimum Order Quantity 1

- Price 425000 INR

- Unit of Measure Piece/Pieces

- Unit of Price Kilograms/Kilograms

For retail or bulk distribution, a sugar packing machine is made to effectively pack sugar into bags or pouches. A hopper that holds sugar, an auger or volumetric filler that measures the sugar, a sealing mechanism that seals bags, and a control panel that manages operations are essential parts. It uses cutting-edge PLC technology to function quickly and precisely. Longevity and hygienic conditions are guaranteed by the machine's sturdy stainless steel construction. It is frequently utilised in the food processing industry and helps manufacturers by increasing production, decreasing labour costs, and improving packing accuracy. It can handle different packing sizes and comes in automatic and semi-automatic varieties.

- Pack Size : 10gm200gm

- Packing Speed : 15 60 Pouches per Minute(Depending on the filling volume)

- Filling Type : Volumetric Cup Filler

- Packing Material : Laminated Film(Heat Sealable)

- Packing Style : Center Sealing

- Accuracy : +/1%

- Machine Dimensions(mm) : 1300x980x2500

- Machine Weight: 750kg(Approx.)

- Model No. : HP101

Tea Packing Machine

Price: 550000 INR /Gram

- Minimum Order Quantity 1

- Price 550000 INR

- Unit of Measure Piece/Pieces

- Unit of Price Gram/Grams

A Tea Packing Machine is designed to efficiently pack tea into sachets, bags, or boxes. Key components include the hopper (holds tea), dosing system (measures tea accurately), sealing unit (seals packaging), and conveyor (moves products for further processes). It operates through automated systems, ensuring high-speed, precision packing. Advanced engineering and manufacturing technologies ensure reliability and long-lasting performance. These machines come in various sizes, from compact to large-scale versions, suitable for different production capacities. Common in the food and beverage industry, tea packing machines improve packaging efficiency, reduce labor costs, maintain hygiene standards, and ensure consistent product quality.

- Pack Size : 10gm 500gm

- Filling Style : Weigh Filler

- Packing Speed : 15- 20 Pouches per Minute

- Packing Material : Laminated Film (Heat Sealable)

- Packing Style : Centre Sealing

- Contact Parts : SS :304

- Model : HP-101 (2 Head)

Kurkure Packing Machine

Price: 275000 INR /Gram

- Minimum Order Quantity 1

- Price 275000 INR

- Unit of Measure Piece/Pieces

- Unit of Price Gram/Grams

A Kurkure Packing Machine is used to automatically package Kurkure snacks into bags or pouches. Crucial components include a snack hopper, a filling mechanism that accurately dispenses quantities, a sealing system that seals packages, and a control panel that monitors operations. The machine incorporates advanced PLC technologies for speed and accuracy. Durability and hygienic advantages are provided by its robust stainless steel construction. It is typically used in the food processing industry and comes in a variety of sizes and models, including automatic and semi-automated variants, to suit varying production levels. It reduces manual labour, improves packaging efficiency, and ensures product quality and uniformity.

- Pack Size : 10gm100gm

- Packing Speed : 45 90 Pouches per Minute(Depending on the filling volume)

- Filling Type : Volumetric Cup Filler

- Packing Material : Laminated Film(Heat Sealable)

- Packing Style : Center Sealing

- Accuracy : +/1%

- Machine Dimensions(mm) : 750x600x2600

- Machine Weight : 450kg(Approx.)

- Model No.: HP95A

Masala Powder Packing Machine

Price: 650000 INR /Piece

- Minimum Order Quantity 1

- Price 650000 INR

- Unit of Measure Piece/Pieces

- Unit of Price Piece/Pieces

An automated device called a Masala Powder Packing Machine is used to package masala, or powdered spices, into jars, sachets, or pouches. It has key parts such a conveyor belt for seamless packing, a volumetric or weight-based filling system, sealing mechanisms, and a hopper for powder storage. Accuracy and speed are guaranteed by the machine's user-friendly control panel. Because it is made with high-quality components, longevity and dependability are guaranteed. It boosts productivity, lowers human error, and guarantees consistent packaging in the food and spice industries. It accommodates varied production scales and packaging styles and comes in a range of sizes.

- Pack Size : 10gm 1kg

- Packing Speed : 15 60 Pouches per Minute(Depending on the filling volume)

- Filling Type : Volumetric Servo Auger Filler

- Packing Material : Laminated Film(Heat Sealable)

- Packing Style : Center Sealing

- Accuracy : +/1%

- Machine Dimensions(mm) : 1500x1200x3000

- Machine Weight : 1050kg(Approx.)

- Material Contact Parts : SS:304

- Model No. : HP102

Beet Molasses

Price: 850000.00 - 900000.00 INR /Number

- Price Range 850000.00 - 900000.00 INR

- Certifications ISO Certificate Provided

- Color Silver

- Computerized No

- Delivery Time 1 Months

- FOB Port Tukalkabada

- Feature Durable

- Main Domestic Market All India

- Material SS

- Minimum Order Quantity 1

- Packaging Details food product

- Payment Terms Cash on Delivery (COD)

- Sample Policy Contact us for information regarding our sample policy

- Supply Ability 1 Per Week

- Type Other, beet molasses

- Unit of Measure Buckle

- Unit of Price Number

Detergent Pouch Packing Machine

Price: 425000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 m3/hr

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Control System Human Machine Interface

- Delivery Time 1 Months

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Pneumatic

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Material Heat sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No. : HP-101 Sealing Type : Center Sealing To Pack : ________ Packaging Range : 10GM-2000GM Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/hr., Supply : 230V(Single Phase) Compressor : 2.5cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Power Motot- 2.5kw/h Watt (w)

- Price 425000 INR

- Supply Ability 50 Per Month

- Type Packaging Line

- Unit of Measure Piece/Pieces

- Unit of Price Unit/Units

- Voltage 230v Volt (v)

- Warranty 1 year

- Weight (kg) 750kg(approx) Kilograms (kg)

Automatic Snacks Packing Machine

Price: 450000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Control System Human Machine Interface

- Dimension (L*W*H) 1300x980x2500 Inch (in)

- Drive Type Pneumatic

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, South America, Western Europe, Middle East, Africa, Asia, Central America, Eastern Europe, North America

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No. : HP-101 Sealing Type : Center Sealing To Pack : Snacks Packaging Range : 10gm- 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/hr., Supply : 230V(Single Phase) Compressor : 2.5cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cash Advance (CA)

- Power Motor - 2.5kw/h Watt (w)

- Price 450000 INR

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230v Watt (w)

- Warranty 1 year

- Weight (kg) 750kg (approx) Kilograms (kg)

Puff Packing Machine

Price: 425000 INR /Piece

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001 : 2008 Certified Company

- Color Silver

- Computerized No

- Control System PLC Control

- Delivery Time 3-4 Week

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Pneumatic

- Feature Heavy Duty Machine, Durable, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Automatic Puff Packing Machine Machine Specification:- Model No. : HP-101 Sealing Type : Center Sealing To Pack : Puff Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/hr., Supply : 230V(Single Phase) Compressor : 2.5 cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions (mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cash Advance (CA)

- Power Motor : 2.5kw/hr. Watt (w)

- Price 425000 INR

- Type Packaging Line

- Unit of Measure Piece/Pieces

- Unit of Price Piece/Pieces

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 750kg(Approx.) Kilograms (kg)

Automatic spices/Powder Packaging Machine

Price: 650000.00 INR /Unit

- Automatic Grade Automatic

- Capacity 30-90 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1200x3000 Millimeter (mm)

- Drive Type Electric

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Model No.- HP-102 Sealing Type : Center Sealing To Pack : Mehndi Packaging Range : 10gm - 2000gm Filling Type : Volumetric Auger Filler Speed : 30-90 Pouches per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : Motor : 7kw/hr, Supply : 230V(Single Phase) Compressor : 4 cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1500x1200x3000 Weight : 1050kg(Approx.)

- Power Motor : 7kw/Hr Watt (w)

- Price 650000.00 INR

- Supply Ability 3-4 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 1050kg Kilograms (kg)

Incepted in 1993, we are betrothed to manufacture, export and supply Automatic Mehndi Packing Machine for our clients. Available in several technical specifications, this machine is perfect for automatic filling and sealing of Mehndi in pouches and bags to assure their safe packaging. It is manufactured with utmost perfection by our seasoned professionals using topnotch quality components and avant-garde techniques in line with international standards. Furthermore, clients can purchase this Automatic Mehndi Packing Machine from us at market leading prices.

Pack Size: 10gm1kg

ï· Packing Speed: 15 60 Pouches per Minute(Depending

on the filling volume)

ï· Filling Type : Volumetric Auger Filler

ï· Packing Material : Laminated Film(Heat Sealable)

ï· Packing Style : Center Sealing

ï· Accuracy : +/1%

ï· Machine Dimensions(mm) : 1500x1200x3000

ï· Machine Weight : 1050kg(Approx.)

ï· Model No. : HP102

Automatic Hi speed Intermitted Auger Filler Machine With Triple Servo

Price: 750000 - 800000 INR /Unit

- Automatic Grade Automatic

- Capacity 30-90 Pcs/min

- Certifications ISO 9001 : 2008 Certified Company

- Color Silver

- Computerized No

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification :- Model No. : HP-103B Sealing Type : Center Sealing To Pack : Fine Powder, Mehndi, Spices, Atta, Maida(Specially fine powder those stucks in hopper) Packaging Range : 10gm - 2000gm Filling Type : Volumetric Auger Filler Speed : 30-90 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Accuracy : +/-1%

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Price 750000 - 800000 INR

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 Year Warranty

Daliya Packing Machine

Price: 525000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-50 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001 : 2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No. :- HP-101(2 Head) Sealing Type : Center Sealing To Pack : Snacks, Tea, Grains, Sugar, Coffee, Spices, Detergent Powder, Salt, etc. Packaging Range : 10gm - 2000gm Filling Type : Weigh Filler Speed : 15-50 Pouches per Minute (Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Accuracy : +/-1%

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Price 525000 INR

- Supply Ability 4 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 Year Warranty

Automatic Form Fill Seal Pneumatic Collar Type Machine with Four Head

Price: 725000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Durable, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No :- HP-101(4 Head) Sealing Type : Center Sealing To Pack : Snacks, Tea, Grains, Sugar, Coffee, Spices, Detergent Powder, Salt,etc. Packaging Range : 10gm - 2000gm Filling Type : Weigh Filler Speed : 15-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Accuracy : +/-1.5%

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Price 725000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 Year Warranty

Automatic Salt Pouch Packing Machine

Price: 425000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia, North America

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Model No : HP-101 Sealing Type : Center Sealing To Pack : Salt Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/Hr. Supply : 230V(Single Phase) Compressor : 2.5 cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Power Motor : 2.5kw/hr Watt (w)

- Price 425000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 750 Kilograms (kg)

Coffee Packing Machine

Price: 725000 INR /Unit

- Automatic Grade Automatic

- Capacity 9-15 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 2100x2000x30000 Millimeter (mm)

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Western Europe, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No : HP-103A Sealing Type : Center Sealing To Pack : Snacks Packaging Range : 10gm - 1000gm Filling Type : Volumetric Cup Filler Speed : 9-15 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor: 5kw/Hr., Supply : 230V(Single Phase) Accuracy : +/-1.5% Dimensions(mm) : 2100x2000x3000 Weight : 1200kg(Approx.)

- Power Motor : 5kw/hr. Watt (w)

- Price 725000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 1200kg Kilograms (kg)

Automatic Sugar Pouch Packing Machine

Price: 375000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Rust Proof, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Model No.-HP-101 Sealing Type : Center Seal To Pack : Sugar Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable laminate Power : Motor:2.5kw/hr., Supply : 230V(Single Phase) Compressor : 2.5 cu Mtrs./Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300X980x2500 Weight : 750kg(Approx.)

- Payment Terms Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Power Motor : 2.5kw/hr Watt (w)

- Price 375000 INR

- Supply Ability 2 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 750 Kilograms (kg)

Spices Powder Packaging Machine

Price: 575000 INR /Unit

- Automatic Grade Automatic

- Capacity 30-90 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1200x3000 Centimeter (cm)

- Drive Type Electric

- Feature Rust Proof, Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Sealing Type : Center Sealing To Pack: Spices Powder Packaging Range : 10gm - 2000gm Filling Type : Volumetric Auger Filler Speed : 30-90 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 7kw/Hr, Supply : 230V(Single Phase) Compressor : 4 cu Mtrs./Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1500x1200x3000 Weight : 1050kg(Approx.)

- Payment Terms Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Power Motor : 7kw/hr Watt (w)

- Price 575000 INR

- Supply Ability 2-3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 Year Warranty

- Weight (kg) 1050 Kilograms (kg)

Automatic Whole Spices Packing Machine

Price: 425000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Sealing Type : Center Sealing To Pack : Whole Spices Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/hr,Supply : 230V(Single Phase) Compressor : 2.5cu Mtrs/Hr. @ 7Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 2.5kw/hr Watt (w)

- Price 425000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 750kg Kilograms (kg)

Atta Packing Machine

Price: 575000 INR /Unit

- Automatic Grade Automatic

- Capacity 30-90 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1200x3000 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification: Sealing Type : Center Sealing To Pack : Wheat Flour Packaging Range : 10gm - 2000gm Filling Type : Volumetric Auger Filler Speed : 30-90 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 7kw/Hr., Supply : 230V(Single Phase) Compressor : 4 cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1500x1200x3000 Weight : 1500kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 7kw/Hr Watt (w)

- Price 575000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 1050kg Kilograms (kg)

Automatic Tea Packing Machine

Price: 425000 INR /Unit

- Automatic Grade Automatic

- Capacity 16-60 Pouches Per Minute Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Sealing Type : Center Seal To Pack : Tea Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/Hr, Supply : 230V(Single Phase) Compressor : 2.5cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 2.5kw/hr Watt (w)

- Price 425000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage Supply : 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 750kg Kilograms (kg)

Horizontal Flow Wrap Machine

Price: 375000 INR /Unit

- Automatic Grade Automatic

- Capacity 40-120 Pouches per Minute Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 3000x1700x1800 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Center Seal To Pack : Biscuits, Cream Wafer Sticks, Cake, Soap, Rusk, Chocolate Bar, Instant Noodles, Engineering Components, Hardware Products, etc. Packaging Range : Length : 70-300,Width : 30-180,Height : 3-100 Feeding Type : Manual/Automatic Speed : 40-120 Pouches per Minute Packing Material : Heat Sealable Laminate Power : Motor : 1HP/AC with AC Drive, Voltage : 220V/440V,Phase : 1 Phase/3 Phase, Load : 3kw Dimensions(mm) : 3000x1700x1800 Weight : 580kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 1HP/AC with AC Drive Horsepower (HP)

- Price 375000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 220V/440V Volt (v)

- Warranty 1 year warranty

- Weight (kg) 580kg Kilograms (kg)

Shampoo Pouch Packing Machine

Price: 850000.00 INR /Unit

- Automatic Grade Automatic

- Capacity 60-70 Strokes per minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1500x3000 Millimeter (mm)

- Drive Type Electric

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Tracks : 6 Track Sealing Type : Four Side To Pack : Liquid & Paste Packaging Range : 0.5ml -250ml Filling Type : Pump Filling Speed : 60-70 Strokes per minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : 7.5kw(Three Phase) Dimensions(mm) : 1500x1500x3000 Weight : 1200kg(Approx.)

- Payment Terms Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Power 7.5kw(Three Phase) Watt (w)

- Price 850000.00 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 year warranty

- Weight (kg) 1200kg Kilograms (kg)

Candy Pillow Pack Machine

Price: 350000 INR /Unit

- Automatic Grade Automatic

- Capacity 300-450 Pouches per Minute Pcs/min

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1080x1000x1360 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Payment Terms Cheque, Telegraphic Transfer (T/T), Cash Advance (CA)

- Power 1HP/AC with AC Drive Horsepower (HP)

- Price 350000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 220V/440V Volt (v)

- Warranty 1 year warranty

- Weight (kg) 700kg Kilograms (kg)

Automatic Form-Fill-Seal Pneumatic Machine

Price: 325000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-45 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 600x1000x1800 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details HP-094 Automatic Form-Fill-Seal Pneumatic Machine Machine Specification:- Tracks : 1 Track Sealing Type : Three Side/Four Side To Pack : Paste, Liquid & Granules Packaging Range : 0.5ml -250ml Filling Type : Pump/Cup Filling Speed : 15-45 Pouches per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : 3kw(Single Phase) Dimensions(mm) : 600x1000x1800 Weight : 500kg Approx.

- Payment Terms Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power 3kw(Single Phase) Watt (w)

- Price 325000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 year warranty

- Weight (kg) 500kg Kilograms (kg)

Automatic Multi Track (4 Track) F.F.S. Machine

Price: 750000 INR /Unit

- Automatic Grade Automatic

- Capacity 40-45 Strokes Per Minute(Depending on the filing volume) Pcs/min

- Certifications ISO 9001:2008 Certified Company

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1500x2100 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, South America, Western Europe, Middle East, Africa, Asia, Central America, Eastern Europe, North America

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Tracks : 4 Track Sealing Type : Four Side To Pack : Powder & Granules Packaging Range : 0.5ml - 100ml Filling Type : Cup Filling Speed : 40-45 strokes per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : 7.5kw(Three Phase) Dimensions(mm) : 1500x1500x2100 Weight : 1100kg(Approx.)

- Payment Terms Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Power 7.5kw(Three Phase) Watt (w)

- Price 750000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Warranty 1 year warranty

- Weight (kg) 1100kg Kilograms (kg)

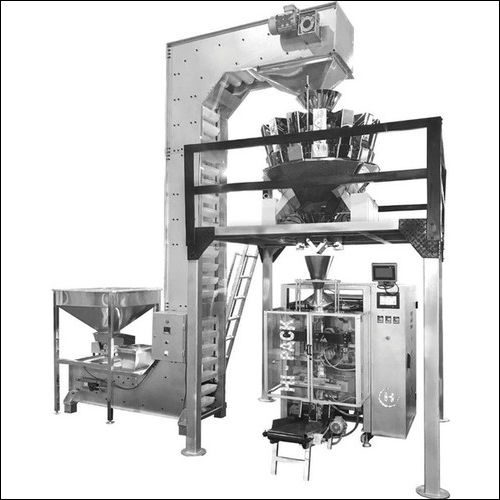

Snacks Packing Machine

Price: 250000.00 INR /Unit

- Automatic Grade Automatic

- Capacity 50-60 Pouches Per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 2100x2000x4000 Millimeter (mm)

- Drive Type Electric

- Main Domestic Market All India

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Multi Weigher with Bagger Machine Specification:- Number of Heads : 10/14 Heads Sealing Type : Center Seal To Pack : Potato Chips, Dry Fruits, Snacks, Pasta, Fries, etc. Packaging Range : 10gm - 1000gm Filling Type : Weigh Filler - Multihead Speed : 50-60 Pouches per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : Motor:7.5kw/Hr., Supply :230V(Three Phase) Accuracy : +/-1% Dimensions(mm) : 2100x2000x4000 Weight : 1800kg(Approx.)

- Power Motor : 7.5 kw/Hr Watt (w)

- Price 250000.00 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Three Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 1800kg Kilograms (kg)

Specification:-

Number of Heads : 10/14 Heads

Sealing Type : Center Seal

To Pack : Potato Chips, Dry Fruits, Snacks, Pasta, Fries,etc.

Packaging Range :10gm - 1000gm

Filling Type : Weigh Filler-Multihead

Speed : 50-60 Pouches Per Minute(Depending on the filling volume

Packing Material : Heat Sealable Laminate

Power : Motor:7.5kw/Hr

Accuracy : +/-1%

Dimensions(mm) : 2100x2000x4000

Weight : 1800kg(Approx.)

Automatic Hi-Speed Collar Type Machine with Double Servo

Price: 700000 INR /Unit

- Automatic Grade Automatic

- Capacity 9-15 Pouches per Minute(Depending on the Filling Volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 2100x2000x3000 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Machine Specification:- Number of Heads : Single Sealing Type : Center Sealing To Pack : Snacks, Tea, Grains, Sugar, Coffee, Spices, Detergent Powder, Salt, etc. Packaging Range : 10gm - 1000gm Filling Type : Volumetric Cup Filler Speed : 9-15 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor : 5kw/hr, Supply:230V(Single Phase) Accuracy : +/-1% Dimensions(mm) : 2100x2000x3000 Weight : 1200kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 5kw/hr. Watt (w)

- Price 700000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 1200kg Kilograms (kg)

Automatic Pneumatic Form-Fill-Seal Auger Filler Machine

Price: 625000 INR /Unit

- Automatic Grade Automatic

- Capacity 30-90 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1500x1200x3000 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Center Seal To Pack : Fine Powder,Mehndi,Spices,Atta,Maida(Specially fine powder those stucks in hopper) Packaging Range : 10gm - 2000gm Filling Type : Volumetric Auger Filler Speed : 30-90 Pouches per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : Motor:7kw/Hr,Supply:230V(Single Phase) Compressor : 4 cu Mtrs/Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1500x1200x3000 Weight : 1050kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 7kw/Hr Watt (w)

- Price 625000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 1050kg Kilograms (kg)

Granules and Powder Packing Machine

Price: 250000 INR /Unit

- Automatic Grade Automatic

- Capacity 200-350 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 900x650x2300 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Three Side/Four Side To Pack : Granules & Powder Packaging Range : 0.5gm - 20gm Filling Type : Volumetric Cup Filler Speed : 200-350 Pouches per Minute(Depending on the filling Volume) Packing Material : Heat Sealable Laminate Power : Motor:0.25hp/0.5hp,Supply:230V(Single Phase),Heating Load :5kw Accuracy : +/-1% Dimensions(mm) : 900x650x2300 Weight : 450kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 0.25hp/0.5hp, Horsepower (HP)

- Price 250000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 450kg Kilograms (kg)

Automatic Form-Fill-Seal Pneumatic Collar Type Machine

Price: 425000 INR /Unit

- Automatic Grade Automatic

- Capacity 15-60 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1300x980x2500 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Less Power Consumable, Highly Efficient

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Western Europe, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Center Seal To Pack : Snacks, Tea, Grains, Sugar, Coffee, Spices, Detergent Powder , Salt, etc. Packaging Range : 10gm - 2000gm Filling Type : Volumetric Cup Filler Speed : 15-60 Pouches per Minute(Depending on the filling volume) Packing Material : Heat Sealable Laminate Power : Motor : 2.5kw/hr, Supply : 230V(Single Phase), Compressor : 2.5 cu Mtrs./Hr. @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 1300x980x2500 Weight : 750kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 2.5kw/hr Watt (w)

- Price 425000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 750kg Kilograms (kg)

Automatic Form-Fill-Seal Machine

Price: 110000 INR /Unit

- Automatic Grade Automatic

- Capacity 60-65 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 900x650x2000 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Western Europe, Asia, Australia, North America, Eastern Europe, Central America, Middle East, South America, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Triangle/Center Side To Pack : Granules & Powder Packaging Range : 0.5gm - 250gm Filling Type : Volumetric Cup Filler Speed : 60-65 Pouches per Minute(Depending on the filling volume Packing Material : Heat Sealable Laminate Power : Motor:0.25HP/0.5HP,Supply :230V(Single Phase),Heating Load: 3Kw Compressor : 2.5 cu Mtrs/Hr @ 7 Bar Accuracy : +/-1% Dimensions(mm) : 900x650x2000 Weight : 350kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 0.25hp/0.5hp, Horsepower (HP)

- Price 110000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 350kg Kilograms (kg)

Automatic FFS Auger Filler Machine

Price: 225000 INR /Unit

- Automatic Grade Automatic

- Capacity 30-60 Pouches per Minute(Depending on the filling volume) Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 1000x1000x3000 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, Africa

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Packaging Details Sealing Type : Three Side/Four Side/Center Seal To Pack : Fine Powder Packaging Range : 0.5gm - 250gm Filling Type : Volumetric Auger Filler Speed : 30-60 Pouches per Minute(Depending on the Filling Volume) Packing Material : Heat Sealable Laminate Power : Motor:0.25/0.5HP,Supply :230V(Single Phase),Heating Load : 5kw Accuracy : +/-1% Dimensions(mm) : 10000x10000x3000 Weight : 550kg(Approx.)

- Payment Terms Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Power Motor : 0.25hp/0.5hp, Horsepower (HP)

- Price 225000 INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 550kg Kilograms (kg)

Automatic FFS Mechanical Machine

Price: nan INR /Unit

- Automatic Grade Automatic

- Capacity 20-45 Pcs/min

- Certifications ISO 9001:2008 Certified

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 750x550x2300 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Asia, Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, North America

- Material Heat Sealable Laminate

- Minimum Order Quantity 1

- Payment Terms Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Power Motor : 0.25hp/0.5hp, Horsepower (HP)

- Price nan INR

- Supply Ability 3 Per Week

- Type Packaging Line

- Unit of Measure Unit/Units

- Unit of Price Unit/Units

- Voltage 230V(Single Phase) Volt (v)

- Warranty 1 year warranty

- Weight (kg) 400kg Kilograms (kg)

Specification:-

Sealing Type : Three Side/Four Side

To Pack : Granules & Powder

Packaging Range : 25gm - 1000gm

Filling Type : Volumetric Pump Filler

Speed : 20-45 Pouches per Minute(Depending On the filling Volume)

Packing Material : Heat Sealable Laminate

Power : Motor : 0.25hp/0.5hp

Supply : 230V(Single Phase)

Heating Load : 2kw

Accuracy : +/-1%

Dimensions(mm)(LxWxH) : 750x550x2300

Weight : 400kg(Approx.)

Chutney Packing Machine

Price: 115000 INR /Piece

- Automatic Grade Automatic

- Auxiliary Packaging Machine Type Sterilizer

- Color Silver

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Dimension (L*W*H) 950*550*1800 Millimeter (mm)

- Drive Type Electric

- Feature Heavy Duty Machine, Highly Efficient, Less Power Consumable

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, Eastern Europe, Middle East, South America, Western Europe, Asia, Central America, Africa

- Material Stainless Steel

- Minimum Order Quantity 1

- Power Motor:0.25hp/0.5hp Horsepower (HP)

- Price 115000 INR

- Supply Ability 1 Per Week

- Type Filling Machine

- Unit of Measure Number

- Unit of Price Piece/Pieces

- Voltage 230v(Single Phase) Volt (v)

- Warranty 1 Year

- Weight (kg) 350kg Kilograms (kg)

Paste & Liquid Packaging Machine

As the professionally driven manufacturer and supplier, we are betrothed in offering Paste & Liquid Packaging Machineto our clients. The provided machine is manufactured at our in-house production unit using premium quality components and pioneering techniques in line with international standards. Ideal for food processing industry, this machine is designed for automated filling and sealing of Paste & Liquid in precise quantities. In addition to this, we offer this Mechanical FFS Machineto our clients in different technical specifications at industry leading prices.

Features:

-

Non-corrosive contact parts to prevent corrosion due to oil and moisture

-

Fully automatic to ensure accuracy in filling & sealing

-

Conveniently placed hopper for continuous filling of snacks

-

Automated weighing chamber for quicker weighing results

-

Synchronized control of spare parts for consistency in packaging

-

PLC based indicative control system for easy operations

Machine Specification:-

Sealing Type : Three Side/Four Side

To Pack : Paste & Liquid

Packaging Range : 0.5ml -250ml

Filling Type : Volumetric Pump Filler

Speed : 30-35 Pouches/Min(Depending on the Filling Volume)

Packing Material : Heat Sealable Laminate

Power : Motor:0.2HP/0.5HP

Supply : 230v(Single Phase)

Heating Load :2kw

Accuracy : +/-1%

Dimensions(mm) : 950*550*1800

Weight : 350kg(Approx.)

Granules Packing Machine

Price: 165000.00 INR /Piece

- Automatic Grade Manual

- Auxiliary Packaging Machine Type Cleaner

- Color Green

- Computerized No

- Control System Human Machine Interface

- Delivery Time 2-3 Days

- Drive Type Electric

- Main Domestic Market All India

- Main Export Market(s) Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Material Stainless Steel

- Minimum Order Quantity 1

- Price 165000.00 INR

- Supply Ability 1 Per Week

- Type Other

- Unit of Measure Unit/Units

- Unit of Price Piece/Pieces

- Voltage 110-440 Volt (v)

|

|

|

HI-PACK & FILL MACHINES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS